ASTM D623 Rubber Compression Flexing Fatigue and Heat Generation

An Introduction to ASTM D623

Written by Rebecca Reiff-Musgrove

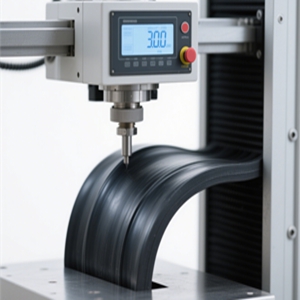

ASTM D623 contains test methods to compare the compressive fatigue characteristics and rate of heat generation of vulcanized rubbers. It describes two methods for applying a rapidly oscillating compressive stress under controlled conditions. Results include the measured temperature rise, degree of specimen dimensional changes and time to fatigue failure (in certain test conditions). In order to fully understand the test setups, procedures, and results requirements, it is important to review the full standard.

What is the test setup?

The test methods in ASTM D623 describe highly bespoke apparatuses, either the Goodrich Flexometer or the Firestone Flexometer, which apply a high-frequency, cyclic compression at a constant applied load. However, the standard KASON software and its Advanced Amplitude Control Module can achieve the same effect without the need for highly specialized equipment.

KASON can advise on appropriate accessories for testing at ambient and non-ambient temperatures.

A key result from ASTM D623 is the temperature rise. KASON supports temperature measurement from a thermocouple transducer, allowing the temperature rise during the test to be recorded.

KASON provides chambers appropriate for testing at non-ambient temperatures, ASTM D623 recommended testing at 50°C or 100°C.

More precise displacement data can be gathered using a LVDT (linear displacement transducer) attached to the platens.

If the applied loads are small in your application, more accurate data can be obtained using a smaller force cell. KASON supports dynamic force transducers down to 250 N.